In the extremely demanding industrial field of oil and gas drilling, drilling pumps are considered the "heart of the drilling rig," and the valve ball and valve seat assembly within the pump are the "valves" of that heart. Their performance directly determines the drilling pump's efficiency, reliability, and lifespan. Among these components, cemented carbide valve balls, with their superior comprehensive performance, have become an indispensable key component of modern high-performance drilling pumps.

The working environment of drilling pumps is extremely harsh. The valve ball needs to cycle open and close hundreds of times per minute, enduring the severe impact from high-pressure mud (pressures can reach over 35 MPa), the intense erosion from abrasive solid particles (such as drill cuttings and barite), and the corrosion from mud chemicals. Ordinary steel valve balls would wear out, deform, or fail rapidly under these conditions, leading to decreased pump efficiency, increased energy consumption, and even drilling shutdowns.

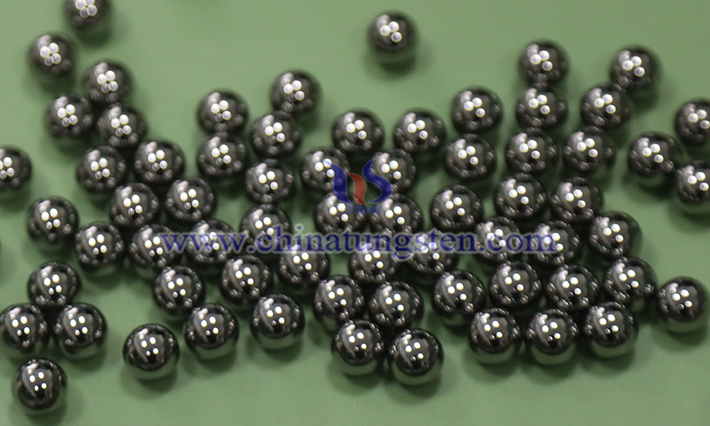

To address this challenge, cemented carbide valve balls were developed. They typically use tungsten carbide (WC) as the hard phase and cobalt (Co) as the metallic binder phase, sintered under high temperature and pressure using powder metallurgy. This material structure gives the valve ball three core advantages:

Extremely high hardness and wear resistance: Tungsten carbide has a hardness exceeding HRA90, effectively resisting the cutting and wear of abrasive particles, resulting in a lifespan dozens of times longer than high-quality alloy steel valve balls.

Excellent strength and toughness: The cobalt binder phase provides good impact toughness, making the valve ball less prone to breakage or fracture under high-pressure cyclic loading, ensuring operational reliability.

Good corrosion resistance: Cemented carbide exhibits excellent resistance to various chemical media in drilling fluids, mitigating corrosion and wear.

In terms of structural design, cemented carbide valve balls pursue extremely high sphericity (true sphericity) and surface finish. The high-precision ball valve body forms an excellent line contact seal with the valve seat, also made of cemented carbide, quickly cutting off high-pressure mud, effectively reducing leakage, and thus maintaining the high volumetric efficiency of the drilling pump and ensuring stable drilling fluid circulation dynamics.

In summary, cemented carbide valve balls, with their unparalleled wear resistance, pressure resistance, and corrosion resistance, greatly enhance the operational capability and durability of drilling pumps in deep wells, ultra-deep wells, and complex geological conditions, reducing maintenance costs and downtime risks. They are a crucial foundation for the modern drilling industry's development towards high efficiency, reliability, and intelligence.