CTIA GROUP LTD tungsten alloy collimators play a key role in medical, industrial and scientific research fields, used to control the direction and range of particle beams, wave beams or radiation beams. In medical diagnostics, they improve imaging accuracy; in industrial inspection, they ensure radiation safety and efficiency; in scientific experiments, they support particle beam guidance. For any tungsten alloy collimator products, please contact CTIA GROUP LTD: sales@chinatungsten.com, 0592-5129595.

1. Material and Structure of Tungsten Alloy Collimators

CTIA GROUP LTD tungsten alloy collimators use tungsten as the main component, supplemented by nickel, iron, copper or cobalt and other elements. Tungsten density is approximately 19.3 g/cm3, making the alloy density reach 16.5–19.0 g/cm3, suitable for radiation shielding. The material has high radiation attenuation capability, high-temperature resistance and mechanical strength, and can maintain stability in high-temperature or vibration environments.

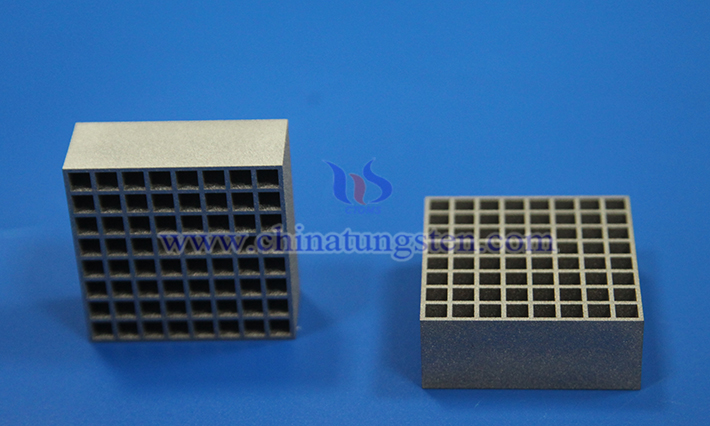

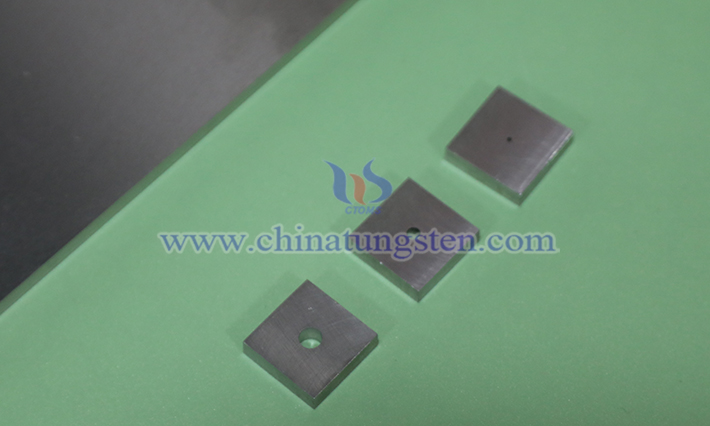

Depending on structural design, CTIA GROUP LTD tungsten alloy collimators can be divided into flat-plate collimators, multi-leaf collimators, annular collimators, conical/pinhole collimators, etc., each differing in actual application scenarios.

2. Working Principle of Tungsten Alloy Collimators

Collimators are based on the interaction between rays and matter, including photoelectric effect, Compton scattering and pair production. These processes cause ray energy attenuation and direction change. The collimator design allows only parallel rays to pass while non-parallel rays are blocked by the tungsten alloy: the photoelectric effect transfers photon energy to electrons; Compton scattering changes photon direction; pair production converts high-energy photons into electron-positron pairs. In this way, control of ray direction and range is achieved.

The working mechanism of collimators under different ray conditions. X-rays: In CT, pre-collimators are located in front of the X-ray tube to shape a fan beam and shield excess radiation; post-collimators are located on the detector side, using tungsten blade slits to reduce scattering interference and improve signal purity. Gamma rays: With high energy and strong penetration, tungsten alloy collimators can attenuate non-parallel rays; applied in industrial flaw detection (defect detection) and nuclear medicine imaging (generating radionuclide distribution images).

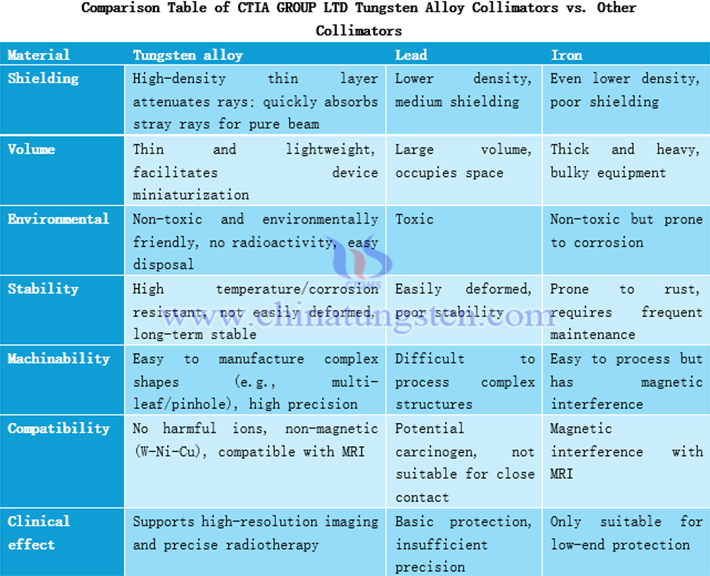

3. Comparison of Tungsten Alloy Collimators with Other Collimators

CTIA GROUP LTD tungsten alloy collimators stand out in medical radiation control due to high shielding efficiency, small volume, non-toxic environmental protection and strong stability, surpassing lead and iron collimators and occupying a dominant position. Although lead was once widely used, its toxicity and large volume have led to gradual elimination; iron is cheap and easy to process but is limited to low-end scenarios due to insufficient shielding, corrosion and magnetic interference.

4. Applications of Tungsten Alloy Collimators

Medical field: In diagnostic imaging (such as SPECT and CT), collimators guide radiation to detectors, reduce stray interference and improve image quality, supporting early disease diagnosis. In radiotherapy, multi-leaf collimators shape radiation beams to target tumors, reduce damage to normal tissue and improve treatment efficacy.

Industrial field: In oil and gas exploration, collimators shield harmful radiation while detecting formation structure. In the nuclear industry, they are used for coded aperture masks to support high-resolution imaging, monitor reactor operation and ensure safety.

Scientific research field: In small animal irradiation platforms, they support cancer therapy research by controlling radiation dose to simulate treatment processes. In neutron scattering experiments, they provide pure neutron beams to study microscopic material structures and promote advances in materials science.

?