When ordinary steel ball bearings reach their limits, tungsten carbide ball bearings enable motors to achieve a leap forward in size, speed, quietness, and durability. Especially in the high-end motor field, where ultimate performance and long lifespan are pursued, they have become an irreplaceable key component.

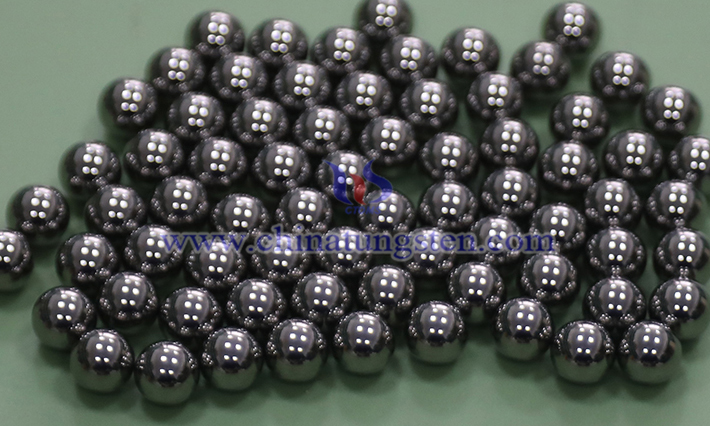

tungsten carbide bearing balls for motors mainly refer to precision balls made of tungsten carbide (WC)-based cemented carbide. They are gradually replacing traditional steel balls in high-pressure, high-speed, and heavy-load motor bearings, and are increasingly widely used in variable frequency motors, servo motors, electric drive motors for new energy vehicles, high-speed rail traction motors, and aerospace special motors.

The core advantage of tungsten carbide bearing balls lies in their extremely high hardness and wear resistance. The hardness of ordinary bearing steel is typically around HRC60-65, while tungsten carbide cemented carbide can easily reach HRA89-93 (equivalent to HRC75 or higher), almost 1.5 times that of steel balls. This means that under the same operating conditions, the wear of tungsten carbide balls is only a fraction of that of steel balls, significantly extending bearing life. This is particularly suitable for industrial motors requiring over ten years of maintenance-free or low-maintenance operation.

Secondly, tungsten carbide has an elastic modulus approximately 2-3 times that of steel, exhibiting extremely high rigidity. The balls deform minimally under load, maintaining higher rotational accuracy. This is especially important for high-speed motors: the higher the speed, the stronger the centrifugal force and gyroscopic effect. Ordinary steel balls experience additional vibration due to minute deformation, while tungsten carbide bearing balls remain highly stable, significantly reducing noise and heat generation, resulting in smoother and quieter motor operation.

Furthermore, tungsten carbide has an extremely low coefficient of thermal expansion and excellent corrosion resistance. It does not easily rust or pit in high-temperature, high-humidity, or even weakly acidic or alkaline environments, making it particularly suitable for motors operating in harsh environments such as wind power, water pumps, and marine engineering.

In addition, although cemented carbide has a higher density (about 15g/cm3, about twice that of steel), in the field of motors, hybrid ceramic ball bearings (i.e., tungsten carbide balls + steel inner and outer rings) or all-ceramic bearings are usually used. Through optimized design, the weight disadvantage is completely offset. On the contrary, the long life and less maintenance brought by wear resistance result in a lower overall system cost.